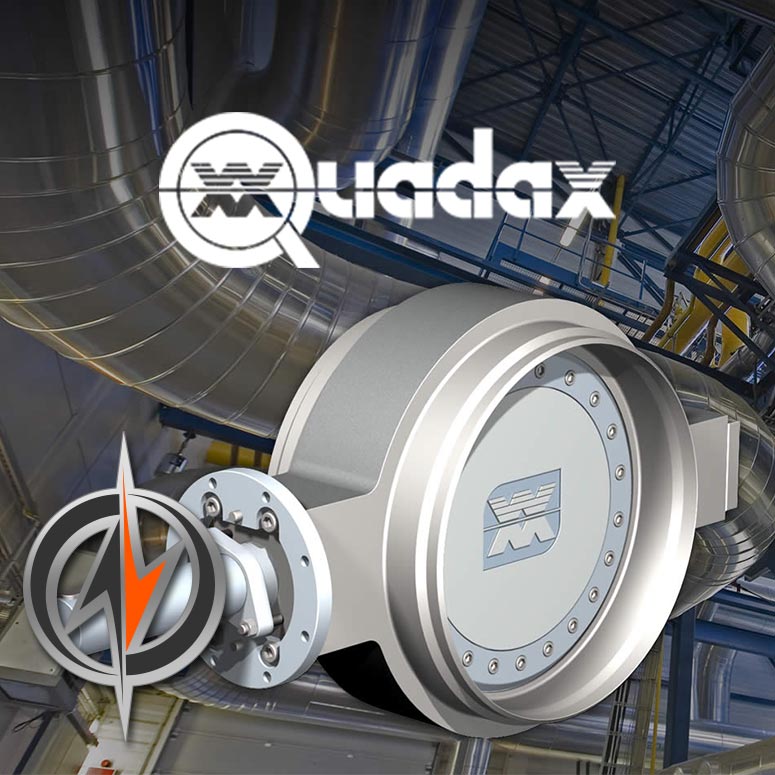

Quadax

QUADAX DESIGN PRINCIPLES

With the new valve series quadax®, the müller co-ax group is expanding the range of products of valves, especially with larger sizes. The unique design, a quadruple (four offset) design and a new manufacturing technology, quadax® meets the highest tightness requirements, even under extreme temperature conditions, ranging from -450 °F to +1,500 °F.

TRIPLE OFFSET COMPARING QUADRUPLE OFFSET

Triple offset butterfly valves have been around for years. With definite advantages over rubber lined and double offset valves, they are currently widely used in industry. Offset 1: The valve shaft is offset from the centerline of the valve seat.Offset 2: The valve shaft is offset from the centerline of the pipe. Offset 3: The disc seal shape is manufactured to the shape of a slice from a round cone whose axis is offset from the centerline of the pipe. The shape of the slice is an ellipse.

THE FOURTH OFFSET

quadax® utilizes a patented seal design that results in a sealing surface that is ROUND. The benefits of a round seal are many, giving us significant advantages over triple offset valves. Offset 4: The cone shape is stretched to an ellipse. The disc seal made to the shape of a slice from this elliptical cone, results in a seal that is perfectly round. The cone shape is stretched to an ellipse. The disc seal made to the shape of a slice from this elliptical cone, results in a seal that is perfectly round.